-

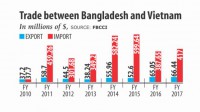

Bangladesh targets $1b trade ties with Vietnam

-

VIETNAM COFFEE EXPORTS UNDER THE TOP 2 OF THE WORLD

-

Rice Exports by Country

-

Relations between Bangladesh and Vietnam

-

Bangladesh Economic Outlook 2019: A resilient economy in need of sound policy LIGHTCASTLE ANALYTICS WING

-

Bangladesh Economy Continues Robust Growth with Rising Exports and Remittances

-

Vietnam beats us in RMG for last 5 months in 2019

-

Bangladesh to seek more Vietnamese investment

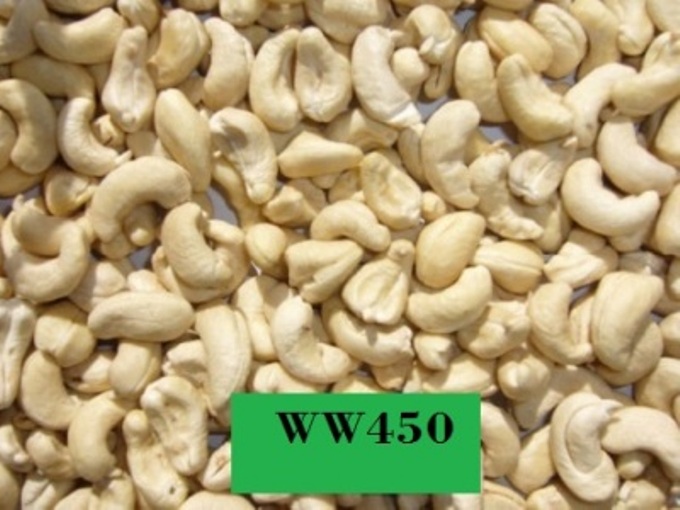

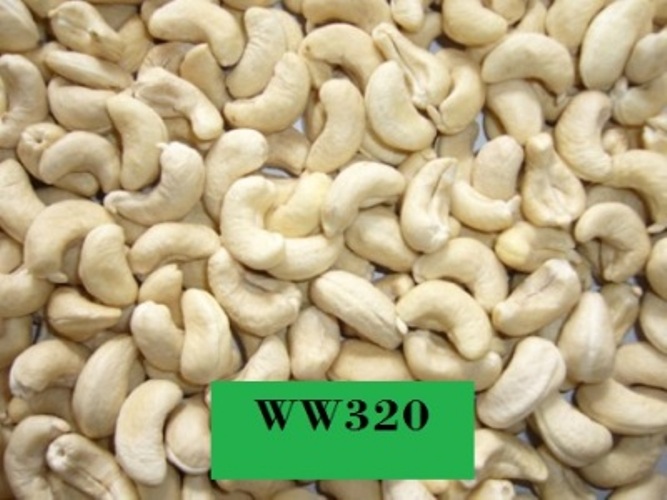

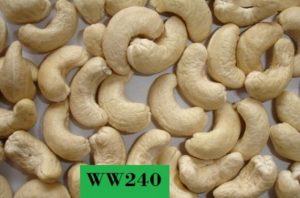

Cashew

Quality according to AFI standard, production line modern, automatic from shredding, silk sorting … we have X-ray machine, color shot machine, metal detector.

WW 450. 320. 240...

Minimum Order Quantity: 1x20ft FCL

Quality Standard : All goods meet AFI (USA 1/2012) Standard.

Packing : in flexi bags with net weight of 22.68kg/bag or client’s requirement

Shipment time: within 20 days from the date of contract

Payment term: Deposit 30%, balance 70% against copy of B/L or 100% L/C at sight

Shipment term: FOB; CFR; CIF as customer’s requirement.

Cashew nut processing

Raw material:

- Raw materials include all types of cashew nuts separated and dried to reach a humidity level below 5%

- The source of raw materials are gathered frp, the factories in the areas of Binh Phuoc, Dong Nai, Tay Ninh. Long An and some other provinces in the country.

- Raw material before transported to the cashew plant checked bu KCS department based on the specific grades of cashew nut kernels.

Grading:

- The grading process is made by machines on types of cashew nuts such as W240, W320, W450...

- The purpose of this process is to classify materials based on grain sizes.

- There are many different grain sizes. Based on each type, we will adjust the size divider accordingly.

- Through this grading process, the grain will reach the required size for export or meet customer requirements for each specific order.

Color sorting process:

- This process is to remove particles with unsatisfactory colors and some strange imporities through the color sensor of the color sorting machine.

- Depending on the standards of each type and each specific customer, we will adjust the level of the sorting machine accordingly.

- Particles after going through this stage will become analogous, suit with export standards about the color as well as percentage of unsuitable particles allowed.

Manual classification:

- Manual sorting is a manual sorting process that adjusts quality to suit orders that are difficult to achieve by sorting machine.

- The particles will be spread out across the stainless steel table and sorted by hand by workers to select fine particles based on visual observation and evaluation.

- Through this process, the grain will achieve overall quality according to export standards.

Fumigation

- This is an important process to ensure that there are no live insects in the products (a serious mistake in exporting agricultural products)

- The grains will be fumigated in a closed room to kill insects.

- This process is conducted withein 7 days

- During this time, all doors and windows of the fumigation room must be absolutely closed.

Detecting impurities and packing:

- This process will be conducted on packaging lines combined with X-ray impurity detection machine.

- The grain will be poured into a stainless steel funnel then go through a shaking sieve to remove small-sized impurities.

- The grains then will be passed through a flat conveyor. The worker will monitor the whole process to remove some visible impurities.

- The end of the conveyor is a big vacuum cleaner to remove dust and light impurities.

- The remaining impurities will be rejected by Xray before being packed.

Metal detectors and loading goods:

- Goods before loading must go through metal detectors for final inspection before being released.

- Containers must be checked to ensure that the side wall and roof panel are not damaged. The floor must be clean and free from scratches.

- The loading of goods onto containers must ensure proper loading of goods, avoid breaking the cartons. Each cartons must be affixed with paper and photographed for control.

- Finally, close the container door and check the seal in accordane with the regulations.

Copyrights Thiet Ke Website by ungdungviet.vn